What is Optical Channel Monitor (OCM)?

2024-11-09

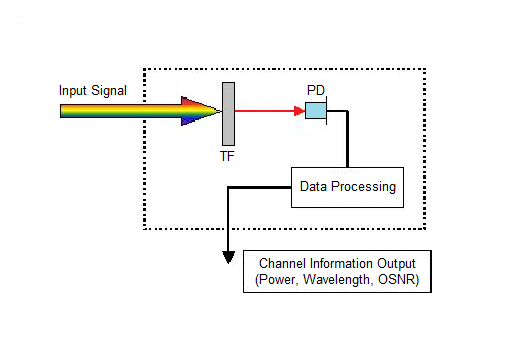

An Optical Channel Monitor (OCM) is an essential device in optical communication networks, specifically in Dense Wavelength Division Multiplexing (DWDM) systems. DWDM networks transport large volumes of data by multiplexing multiple optical signals on distinct wavelengths. As network operators strive to maximize data throughput and maintain network reliability, monitoring and managing these optical channels becomes paramount. This is where OCM technology plays a critical role, enabling continuous, real-time monitoring of optical signal channels. OCMs provide vital information on signal quality, helping network operators make adjustments to ensure stable, high-quality transmissions.

OCMs are generally classified based on their monitoring scope and operational modes. The main types include:

1). Full-Band OCMs

Full-band OCMs monitor the entire optical spectrum within a DWDM network, typically covering C-band and L-band frequencies. They are advantageous for large-scale networks with many wavelengths, as they can simultaneously monitor every channel. Full-band OCMs are particularly useful in long-haul and ultra-long-haul optical networks.

2). Channelized OCMs

Channelized OCMs monitor individual wavelengths or specific groups of channels. These devices provide precise control and higher resolution over selected wavelengths, which is useful for targeted monitoring in networks where only a few channels need oversight. Channelized OCMs are frequently used in metro and access networks.

3). Embedded OCMs

Embedded OCMs are integrated directly into network devices like optical amplifiers or transponders. This compact design allows them to provide real-time monitoring of specific points in the network, reducing latency in fault detection. Embedded OCMs are ideal for applications that require tight integration and fast response times.

4). Stand-alone OCMs

Stand-alone OCMs are independent units typically installed at network hubs or data centers to monitor entire optical networks. They offer a higher degree of customization and flexibility, allowing network operators to manage and monitor multiple channels across vast geographical regions. Stand-alone OCMs are well-suited for core network applications.

The use of OCM technology spans various sectors, playing a critical role in ensuring data quality and network reliability:

1). Long-Haul and Ultra-Long-Haul Networks

OCMs are integral to long-haul networks that transmit data over thousands of kilometers. In these systems, optical signals degrade over distance due to factors such as attenuation and dispersion. OCMs help maintain signal integrity by monitoring channel performance and enabling network operators to apply corrective measures when necessary.

2). Data Centers

Data centers host numerous DWDM channels to manage the high data demands of cloud computing, AI applications, and big data processing. OCMs ensure efficient channel utilization, helping optimize bandwidth and reduce the risk of signal degradation due to high traffic loads.

3). 5G Networks and Fiber-to-the-Home (FTTH)

In high-bandwidth networks like 5G and FTTH, OCMs monitor the optical signals that support high-speed data transmission to individual users. This helps maintain signal quality and reduce latency in bandwidth-intensive applications.

4). Disaster Recovery and Redundancy Management

For networks that rely on redundant pathways to ensure continuous service, OCMs offer critical insights into channel performance across primary and backup routes. This capability enhances disaster recovery by alerting operators to channel degradation before a primary path fails, allowing a seamless transition to secondary routes.

Optical Channel Monitors provide numerous benefits that enhance the quality, efficiency, and reliability of optical networks. By monitoring signal quality and wavelength accuracy, OCMs improve network resilience and minimize downtime. In cases of unexpected channel interference, OCMs aid in rapid problem resolution, allowing operators to restore service quickly. Additionally, these monitors reduce operational costs by automating tasks that would otherwise require manual inspection, saving time and resources.