Differences between FBT Splitter and PLC Splitter

2022-01-21

Fiber optic splitter is an important component in FTTx and PON architectures, enabling multiple users to share the optic network. The most common types of optic splitters are FBT (fused biconic taper) splitter and PLC (planar lightwave circuit) splitter.

PLC Optic Splitter

PLC Splitter is an integrated waveguide optical power distribution device based on quartz substrate, featuring small size, wide range of working wavelength, high reliability and good spectral uniformity, especially suitable for passive optical network (EPON, BPON, GPON, etc.) to connect the local end and terminal equipment and achieve optical signal splitting.

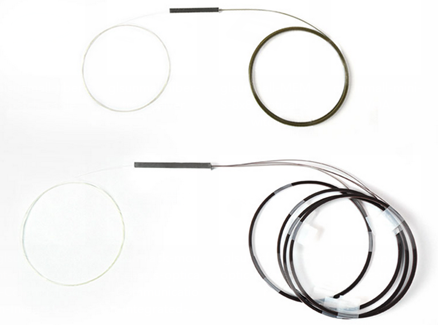

FBT Optic Splitter

FBT Splitter is to bundle two or more optical fibers together, and then fuse and stretch them in the taper puller, and monitor the change of the optical splitter ratio in real time. The fusion process is ended when the splitting ratio reaches the required standard, with one end retaining an optical fiber (the rest is cut off) as the input terminal, and the other end as multiple output terminal.

Differences between FBT and PLC Splitters

PLC and FBT may be similar in size and appearance, there are many differences when it comes to actual applications. It is important to know their differences and choose the most suitable one for your network.

1. Material

Fiber splitters are made of steel, fiber optics, heat shrinkable tubes and other common materials. The cost of these materials is not high, and the device manufacturing technology is relatively simple, so the price of FBT optical splitter is relatively cheap. The manufacturing of PLC optical splitter involves semiconductor technology, making it more complex and costly.

2. Working Wavelength

FBT optical splitter only supports three wavelengths, which are 850nm, 1310nm and 1550nm, and it does not work on other wavelengths. PLC optical splitters support a wider operating wavelength range at 1260nm - 1650nm.

3. Splitting Ratio

The splitting ratio of FBT fiber splitter is can reach 1:32, while that of PLC fiber splitter can rise to 64, which enables PLC fiber splitter to provide higher reliability. Based on more advanced technology, PLC fiber splitter can be split optical signals equally.

4. Temperature

Temperature is the key factor affecting the performance of optical devices. Therefore, good temperature stability plays an important role in the performance of equipment. FBT splitter can work stably at -5℃ to 75℃, while PLC spliiter can work and perform well at a wider temperature range at -40℃ to 85℃.

Summary

With the development of splitter technology, PLC splitter is overall a more advanced and reliable type of device compared to traditional FBT splitter. The relatively more compact size of PLC splitter as compared to that of FBT splitter makes PLC splitter more suitable for high density applications. On the other hand, FBT splitters are less expensive and can save more for the budget. The key to choosing the most suitable one is based on the needs and application scenario.

If you are looking to build or upgrade your network using the above devices, it is important to source them from a reliable supplier. As a competent manufacturer with 20 years experience in fiber optic communication, Guilin GLSUN Science and Tech Group Co., Ltd offers reliable products, professional network solutions and technical support.